What once sounded like a futuristic fantasy is now a present day reality and is bringing classic cars of the past back to life. We are talking about the evolving technology of 3D printing.

What once sounded like a futuristic fantasy is now a present day reality and is bringing classic cars of the past back to life. We are talking about the evolving technology of 3D printing.

The rapid advancement of 3D printing technology now makes it possible to re-create those near impossible parts to find. Materials like plastic and metal can be fed into these printers to produce parts to such high tolerances and to exact specifications just like they came out of the factory.

Without 3D printing the only option to create a new part would be to develop and tool them. Tooling a part is not cost effective. A manufacturer may have to produce and sell thousands of a certain part to recoup their money from that lengthy process. With 3D printing you have the option of making just one part much faster and far cheaper.

Parts are created in virtual CAD software to get the exact shape and dimensions and the actual manufacturing of the part can now be made in a matter of hours. The parts will likely still have to be finished, chromed, etc., but the actual creation process can now be cut down to a matter of weeks, days or in some cases hours.

A relatively new company called Freshmade 3D is leading the way with creating hard to find parts for classic cars and trucks. They are currently partnered with Hahn-Vorbach, a restoration company from Pennsylvania, and together they are restoring classic cars with brand new replica parts printed by Freshmade 3D.

“We can give you a perfectly functioning metal part that’s either been enabled by 3D printing or literally 3D printed.” said Freshmade 3D president and COO Christopher Tomko.

“It could be a rusted part that we start with. Then we have to start putting together a little bit of our knowledge to figure out how to get it to our actual part geometry,” said chief technical officer Brett Conner. “In the traditional sense, you’re usually waiting years to get the parts. Now in this case, you can get it in a few weeks”.

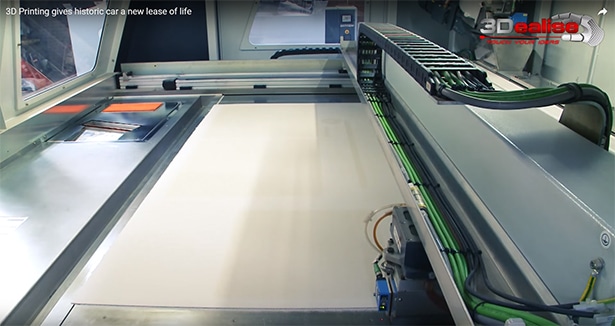

Another company in Europe called 3Dealise is doing something similar. They were able to use 3D printing technology to rapidly prototype a casting mold for a 1912 one-cylinder engine that may otherwise have been impossible to find or recreate. You can watch the entire process in the video below.

With 3D printing technology rapidly advancing it might not be long before you can drive down to a local printing shop and tell them what you need. If the virtual design is already available you could get your part in a matter of hours. We suspect that in the future a 3D printer will be a go-to tool in every restoration shop or even home garage.