The electric car horn we commonly see in our classic cars and trucks has been around for quite a while although it was not the first method of alerting others that a vehicle may be posing a danger. In fact there was a law in Britain back passed in 1864 that stated every mechanically propelled vehicle traveling upon any public highway needed to be proceeded by a pedestrian walking 120 feet in front of the vehicle with a large, red danger flag.

Can you imagine someone walking 120 feet in front of every car waving a flag? Besides only being able to drive 4 mph, it would look simply ridiculous. This is why we owe a huge amount of thanks to Oliver Lucas for inventing the electric car horn back in 1910. Oliver gave us all the opportunity to both warn others of imposing danger, but also gave us the joy of letting everyone know that we have arrived and the ability to honk at the cute girl walking down the street.

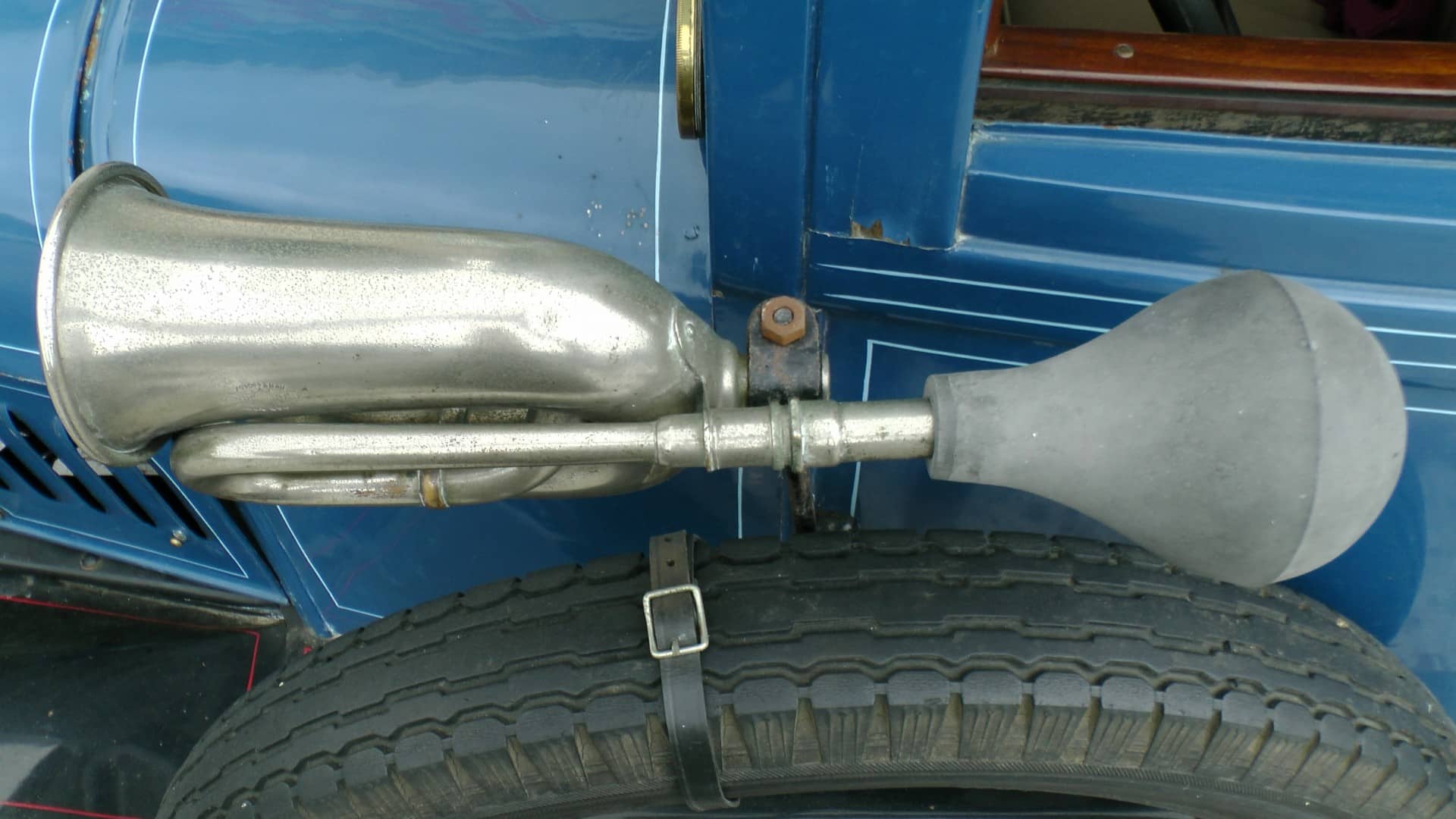

The electric car horn design and functionality has remained relatively unchanged for a century! There are basically two types of vintage car horns. There is the trumpet style horn that can range anywhere from a few inches long to a foot or more. These trumpet horns are seen one much more vintage types of automobiles. The more common type of horn you will find in your classic car, muscle car or hot rod is the more compact snail shell horn design. All horns are typically mounted right behind the front grille to provide maximum decibels.

When horns were first released to the public they were often controlled by a button that was mounted to the dash. This was certainly not convenient if you needed to sound the horn in a hurry. It didn’t take long to figure this out and by 1915 the Scripps-Booth Model was the first car to add the horn button to the center of the steering wheel driving column. It was quickly obvious that the horn button needed to be close to the hands.

The next major advancement in car horn technology was simply adding a second horn under the hood. Tuning each horn to different tone frequencies allowed the human ear to instantly recognized the horn. One horn could sometimes get drowned out in loud traffic and city noises. It also created a backup system in case one went down.

While the horn has become a slightly more complex piece of equipment over the past century, it still is one of the most basic parts in an automobile and is fairly easy to diagnose any issues. A horn works by charging an electromagnet that vibrates a thin steel diaphragm built into the snail shaped amplifier. On most automobile horns there is a screw that will allow you to get the best sound by adjusting the distance between the electromagnet and the diaphragm.

Depending on the year, make and model of your vehicle there may be different ways of getting the horn to sound. In most classic cars and trucks you will have a button or strip on the steering wheel or a button on the center steering wheel column. Connecting the contacts by pushing the horn button allows electricity to flow from the battery to a horn relay. If the button is on your steering wheel then the signal from the button travels through a contact ring and brush to allow the power to flow regardless of the steering wheel position.

Once power arrives at the horn relay a magnetic coil is charged inside the relay which then closes the contacts allowing battery voltage to flow to the horn itself. This setup is used because horn circuits can draw a lot of amperage. In most cases the amp draw is somewhere around 5-9 Amps making it one of the most power-hungry accessories in the automobile.

Thanks to the simplicity of the circuit, locating malfunctions only requires a few tests. However, an assistant comes in handy to push on the horn button while these tests are performed. The first thing to determine when a classic car horn is inoperative is whether there is a good power source and ground at the horn.

Checking for power can be done with a test light or multi-meter while the someone else pushes the horn button. On many vintage cars the horn is case grounded. This means it receives ground from where it’s bolted to metal car parts. When only one wire connects to the horn this indicates a case grounded horn set up.

If no power is reaching the sound device it’s time to check the fuse. Most manufacturers have a separate fuse that operates the horn. Should the fuse test pass, it’s time to find the relay and see if you have power coming in and going out of the relay. Failed or malfunctioning horn relays are a common source of problems. If no power is reaching the relay from the steering column, then a malfunction of the horn contacts or the brush and slip ring are most likely the cause.

When you do have good power and ground at the sound device, yet it refuses to honk or responds in a weak manner, corrosion inside or damage to the thin metal diaphragm are likely causes of malfunction. The older the automobile the more likely this problem will occur. For classic car owners that wish to retain the original parts, there are specialized companies that repair classic car horns. These folks actually disassemble the sound device and replace the electromagnet and diaphragm inside.

If keeping the car completely original isn’t that important to you, then it would probably be cheaper to just buy a new aftermarket horn. If you really want to take your horn game to the next level then get yourself the Big Bubba programmable car horn. You can upload any MP3 sound you would like your horn to make which could be pretty funny if it were to get into the wrong hands.